Ultra-high Speed Boxed Checkweigher Industrial Checkweigher Machine System

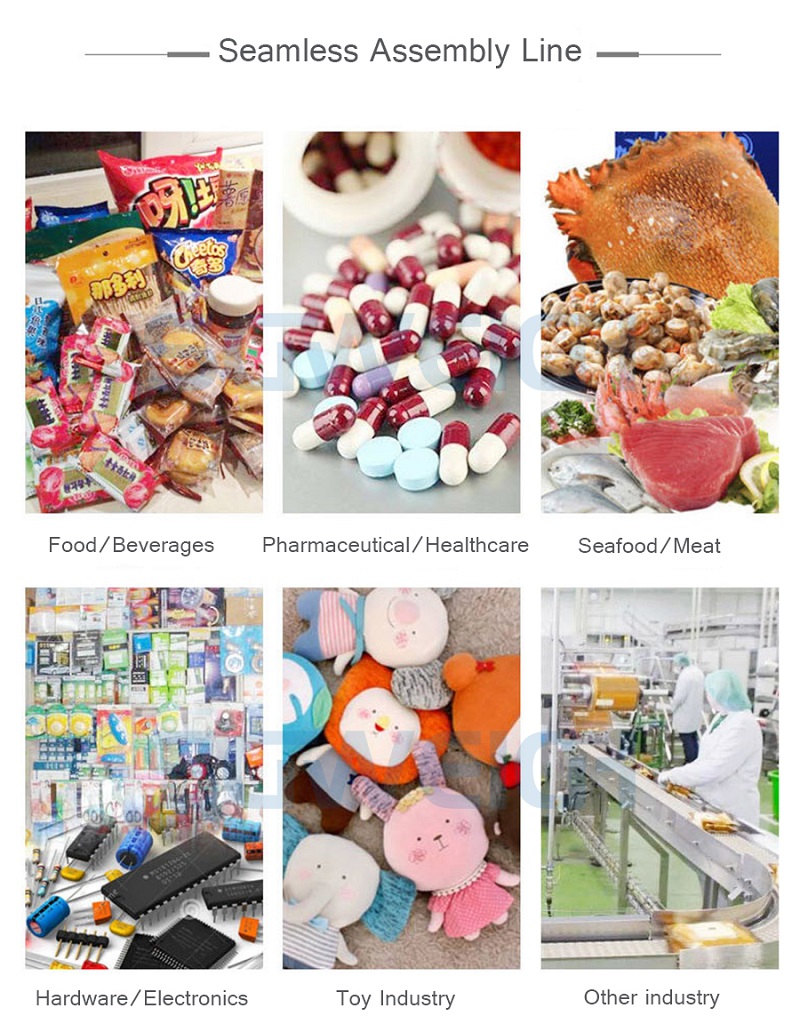

A ultra-high speed boxed checkweigher is a device used to accurately measure the weight of a product, while a reject system is used to remove substandard or out-of-weight products from the production process. This type of industrial checkweigher machine system is particularly important in the food, pharmaceutical, chemical and other industries as it helps ensure consistent product quality and safety. Our products have a wide range of specifications, sizes, and styles, providing various customized solutions. Welcome to contact us.

Ultra-high speed boxed checkweigher pictures

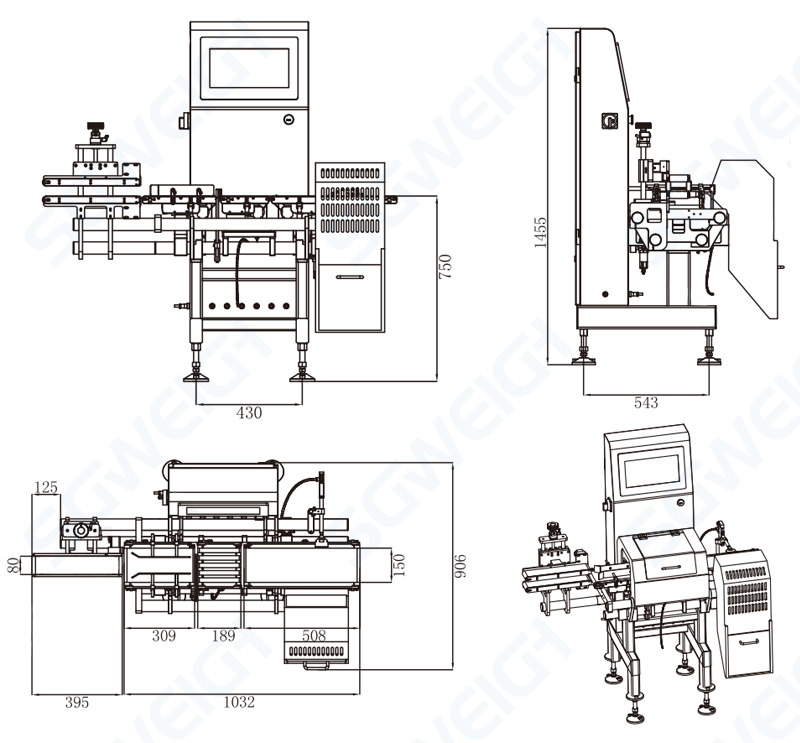

Type SG-150HH

Weighing Range 3-500g

Limited of product L: 100 W:150 H: 2-150mm

Accuracy ±0.1g Depends on product

Division Scale 0.1g

Belt Speed 0- 110 m/min

Max Speed 450 pcs/min

Belt Width 150mm

Machine Weight 140kg

Power Supply 50HZ

Power 200W

Main Material SU304 stainless steel

How to select products?

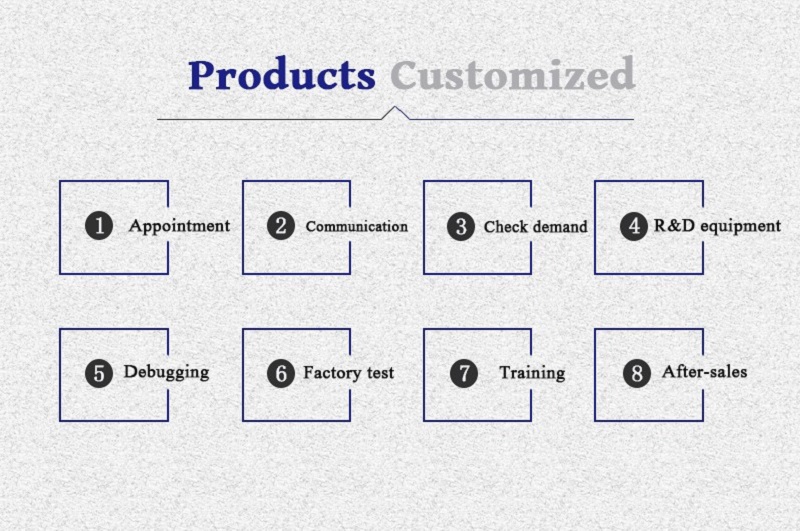

Answer: Step 1: Determine the series based on the size, weight range and use of the products you need to sort.

If the weight is within 300g and the size is 150*90*30mm, it is more appropriate to choose the model SG-150. The belt width is 150mm and the range is within 500g.

The second step is to determine the levels you need to sort, whether it is three levels or five levels. Different levels have different prices. The more levels, the higher the price. Currently our factory can sort up to 12 levels.

The third step is to determine the height, width (if any) of your existing assembly line, and the space our company needs.

The fourth step is to determine the optional functions you need; such as USB data storage, real-time transmission of weight data, alarms, etc.

In order to provide more accurate parameters, plans and quotations, it is recommended that you contact the person in charge of our company to help you complete the selection.

Ultra-high speed boxed checkweigher is widely used in the production and packaging processes of food and beverage, pharmaceutical, daily chemicals, warehousing and logistics, electronic light industry, packaging and printing, auto parts and hardware, plastic toys, chemicals, agricultural and sideline products and other industries.

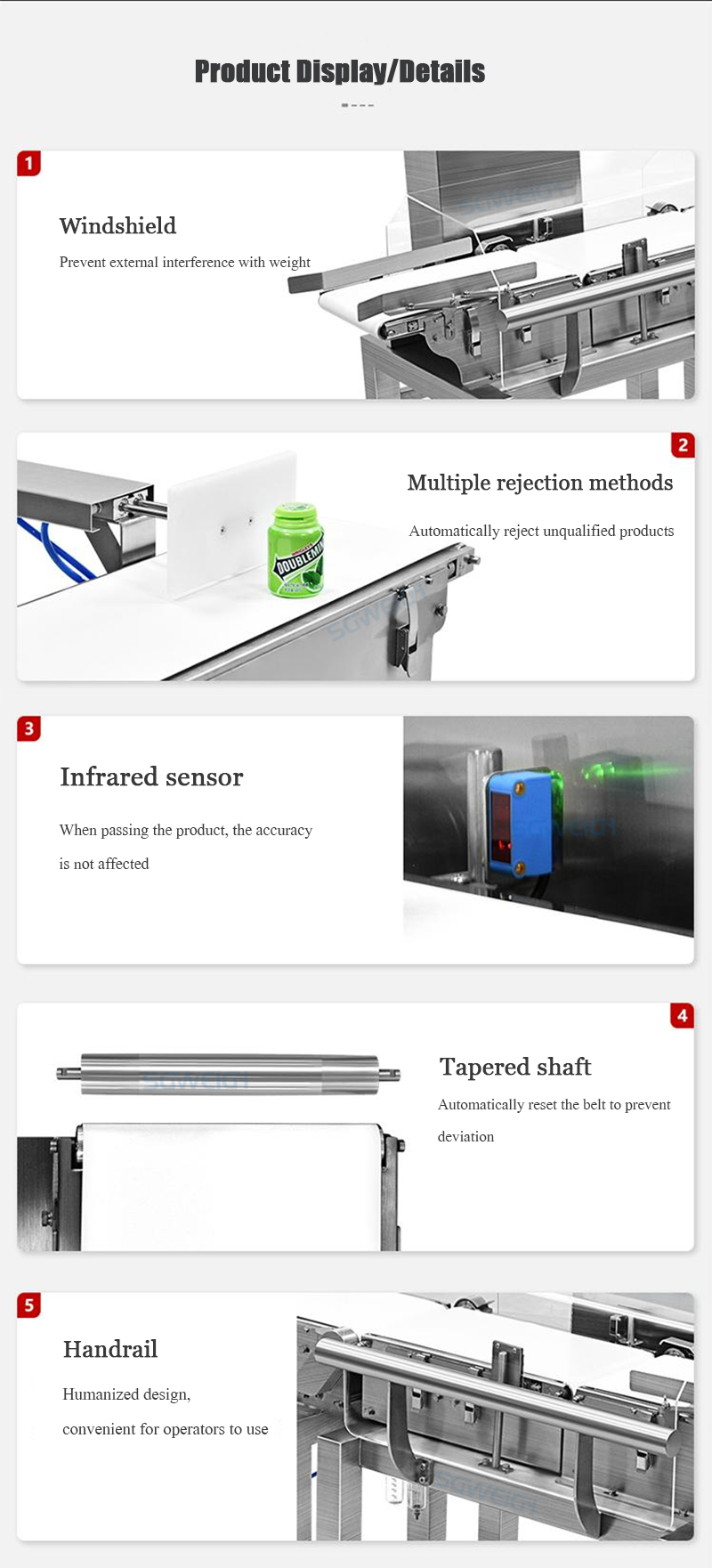

- User-friendly operating system.

- Chinese-English interface.

- Weight of products can be compensated.

- Product qualification ratio can be showed in line graphs and bar charts

- Three-level operation authority management, support self-set password

- 100 kinds data can store with strong data statistics function.

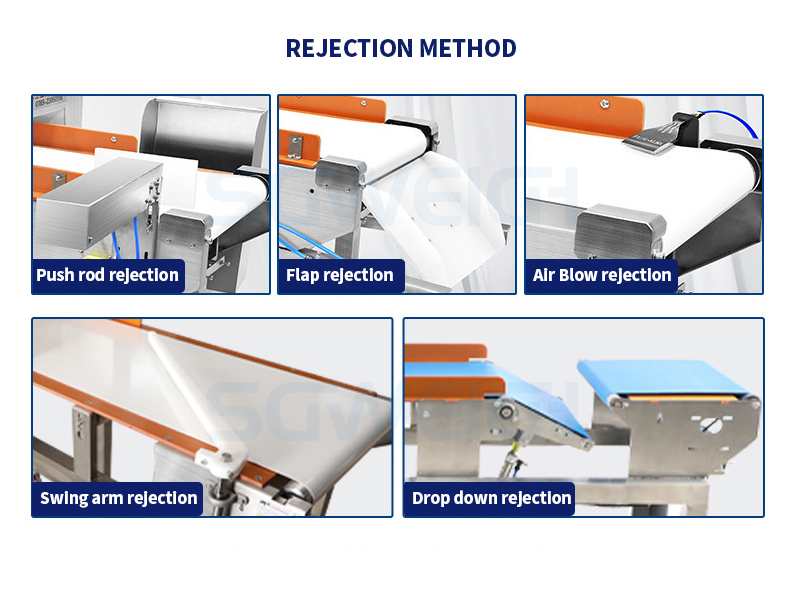

- Support multi-methods of rejection.

- Press box device can be added

Shanghai Shigan Industrial Co., Ltd. is a checkweigher machinery automation equipment manufacturer integrating R&D, design, production and sales. Located in Shanghai, China, a developed area in the machinery industry, we adhere to the principle of “excellent service and good quality”. The company has complete equipment and independently produces various types of mechanical transmission and hardware accessories. The courage to research innovative technologies and continuous improvement has won unanimous praise from the majority of enterprises. Shanghai Shigian has always been committed to the R&D and manufacturing of a series of weighing equipment such as checkweigher machines, digital metal detectors,weighing labeling machines, checkweigher with metal detector combo, and etc,.

Packing Detail:

Each Machine with plastic film package first, then placed in a wooden case, wooden case with a foam filling.

We loaded the truck with heavy trucks for loading the cargo to the harbor terminal.At the dock we pack the goods in containers and ship them abroad.

Delivery Detail :

Shipped in 15 days after payment

1. Customer consultation and technical support: Provide customers with consulting services on product use, repair and maintenance, and answer problems encountered by customers during operation and use.

2. Technical training: Provide training on product operation, maintenance and repair according to customer needs to ensure that customers can use and maintain products correctly.

3. Accessories supply: Provide original accessories to ensure the quality and performance of the accessories and meet the needs of users.

4. One-year warranty and lifetime maintenance

6. After-sales service tracking: Track and provide feedback on the after-sales service process, understand customer needs and opinions in a timely manner, and continuously improve service quality.

Related Products

50ml Spraying Assembly Line Checkweigher

Pills Capsule Small Vertical Metal Detection Machine

Small Bottle Check Weigher for Pharmaceuticals

High Performance Small Box Industrial Check Weigher

Small Aluminum Foil Pouch Tea Metal Detector

Multi-purpose Canned Food Metal Detector

Hot Labels:ultra-high speed,boxed,checkweigher,industrial checkweigher machine,system,manufacturer,price,factory