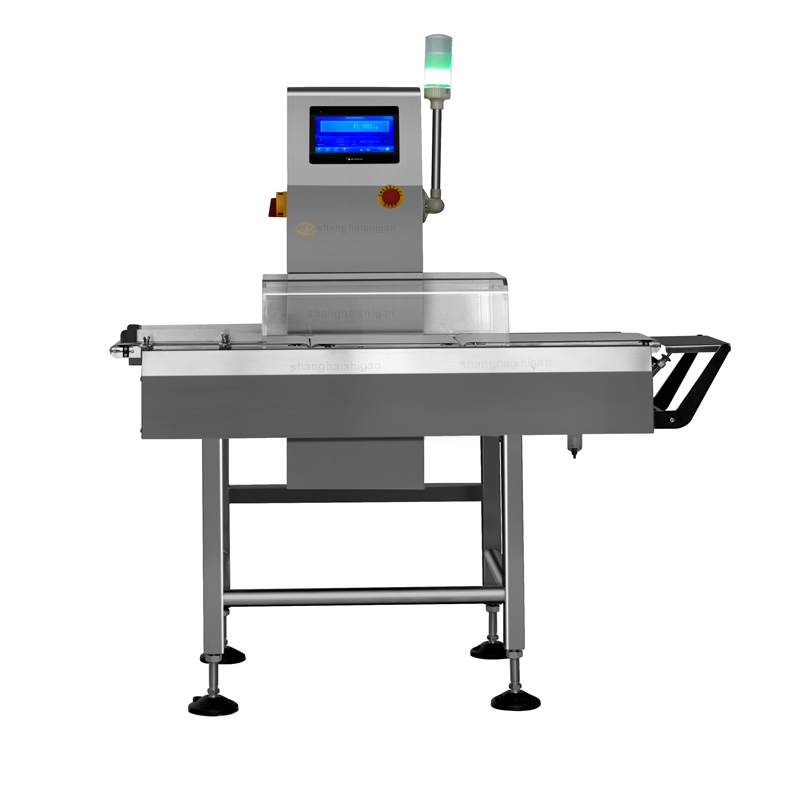

Food Checkweigher Machine Automtaic Check Weighing Machine for Glass Bottle Pickle Processing Line

Product Introduction

The high accuracy food checkweigher for bottle is equipped with an automated online dynamic weighing control system and an automatic zero-point tracking system to ensure reliable test data. It has an embedded temperature and noise compensation system to ensure system stability. Automtaic check weighing machine has been verified by actual client applications for many years and is stable and reliable. The checkweigher adopts a humanized operating system design, which is easy to learn and operate, and is available in multiple language versions. Any OEM and customer design orders are welcome! If you are interested in our products, please feel free to contact us.

High accuracy food checkweigher for bottle photos

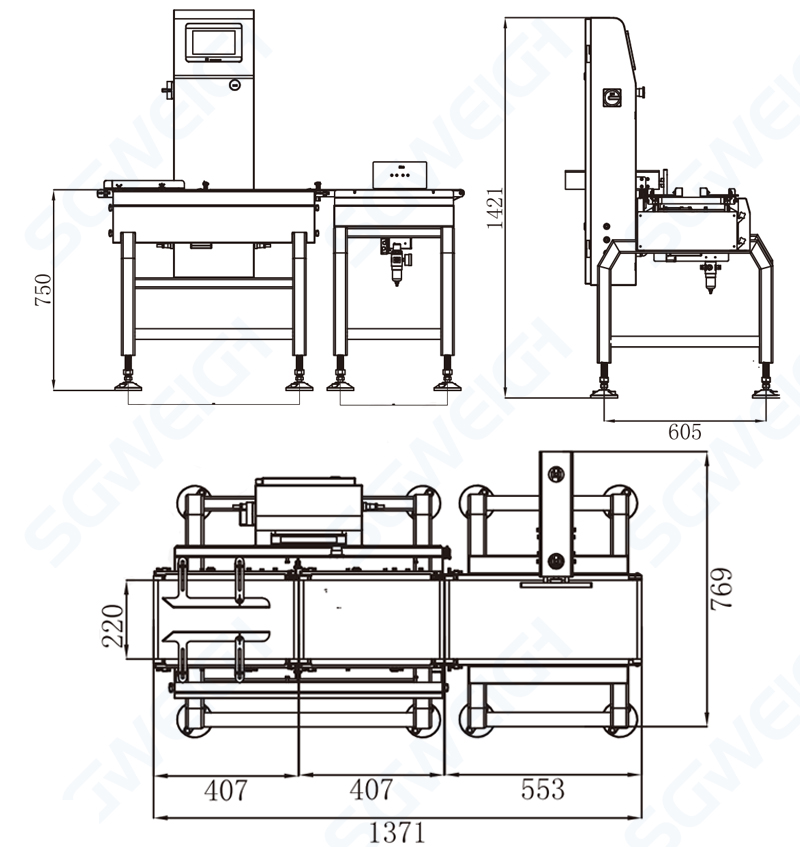

Technical Parameter

Type SG-220

Weighing Range 5-1500g

Limited of product L: 300 W:220 H: 3-200mm

Accuracy ±0.2g Depends on product

Division Scale 0.1g

Belt Speed 0- 60 m/min

Max Speed 100 pcs/min

Belt Width 220mm

Machine Weight 85kg

Power Supply AC-220V 50HZ

Power 200W

Main Material SU304 stainless steel

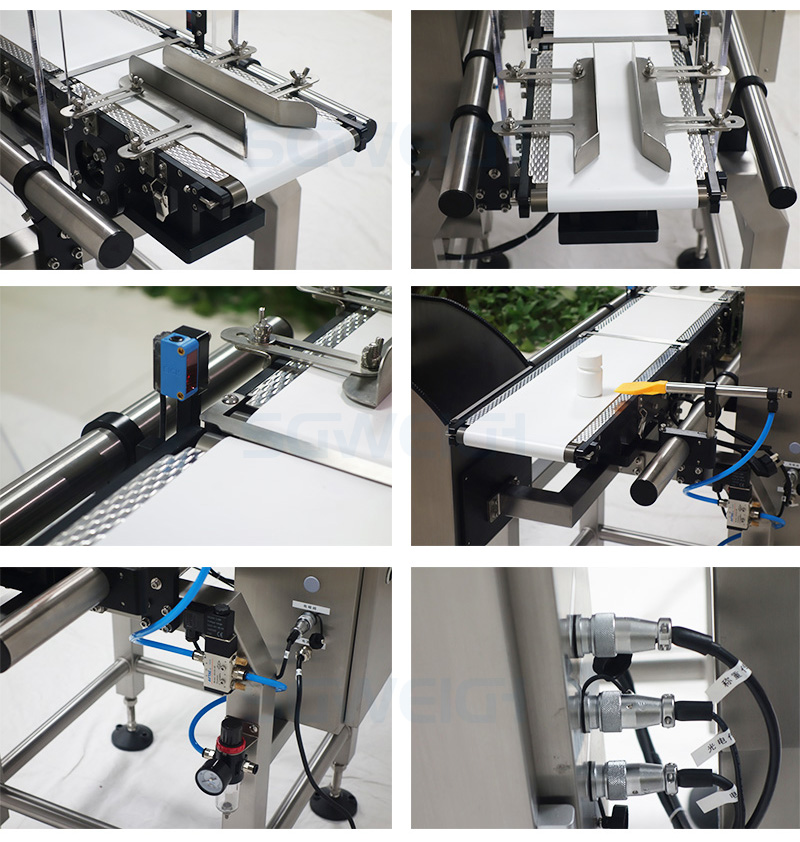

Product Details

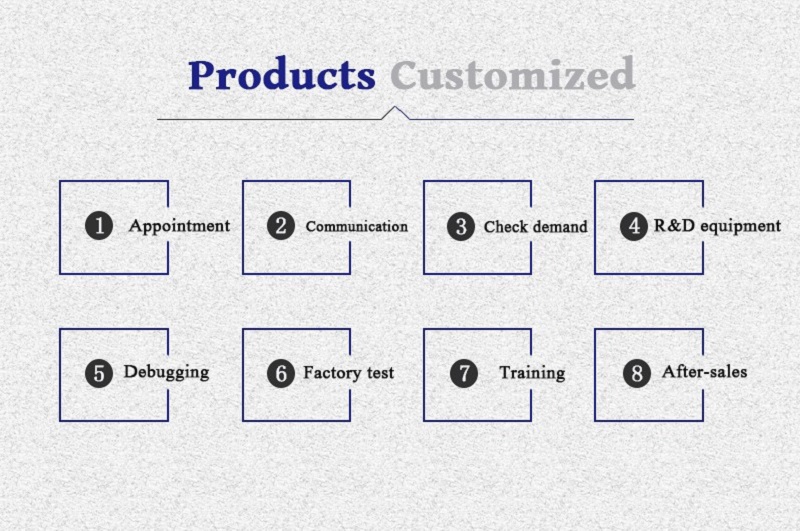

Customized Process

1st step: Customer has showed his special requirements.

2nd step: We try to understand the conception and pattern from customer with simple draft or refer picture.

3rd step: Making the conceptive CAD drawing based on communication and understanding.

4th step: Making the detail and 3D drawing agter fixed the design and other details.

5th step: Offer the quotation after confirm the design,material and surface treament.

6th step: Making the sample for approval.

7th step: Testing installation after demo mock up.

8th step: Big production delivery and service after sales.

Main Features

1. Accurate and efficient rejection system.

2. Switch products in seconds, with a stored product library of up to 100 products.

3. Multi-level password protection for secure access and traceability.

4. Extensive data logging and reporting via USB or Ethernet for HACCP and retail compliance.

5. Automatic average weight correction to help meet weight legislation requirements.

6. Ultra-high-speed dynamic weight tracking and automatic compensation technology to effectively improve detection stability.

7. Brushless motors and proven conveyor components are designed for reliable operation around the clock.

8. Dynamic weighing for large terminal packaged goods, including convenience foods, pouches and ready meals.

Application Scope

Automatic checkweigher machines can be used in food, pharmaceuticals, plastics, chemicals, textiles, clothing, toys, papermaking, sanitary products, electronics, renewable resources and other industries.

Company Profile

Shanghai Shigan Industrial Co., Ltd. was founded in 2010 and is located in Shanghai. Shanghai Shigan has an independent large-scale R&D organization, a complete production and manufacturing system and a huge marketing service network. It is an international assembly line testing equipment manufacturer integrating R&D, manufacturing, marketing and services. At present, our company’s products have passed the CE EU certification and are exported to many countries and regions such as Europe, the United States, Singapore, Thailand, etc. The products are widely used in food, medicine, daily chemicals, chemicals, agricultural and veterinary drugs and other industries. Over the years, the company has continuously carried out technological transformation, and the product quality has been significantly improved, which has been highly recognized by domestic and foreign customers. The main products are: automatic checkweighers, digital metal detectors, weighing and labeling machines, etc.

Our Customers

Our Exhibition

Packing & Shipping

The Delivery Date: After receiving the payment, the delivery date will be within 15-30 working days

Packaging: Protective film + wooden case

Logistics: Air, sea or express (DHL, etc.)

The Freight: The cost of transport depends on the destination, mode of transport and the weight of the goods

Pay: T/T, Western Union, paypal

After-sale Service

Pre-Sales Service

1.Inquiry and consulting support.

2.Sample testing support.

3. View our Factory.

After-Sales Service

1.Training how to instal the machine, training how to use the machine.

2.One year warranty, lifetime repair

Related Products

Full Square Pack Tissue Digital Metal Detection Machine

High Speed Small Package Screw Checkweigher

High Performance Bottle Rotary Weighing Check Weigher

Automated Checkweigher and Metal Detector System

Online Capsule Tablet Sample Checkweigher Equipment

Vertical High-speed Capsule Tabelt Metal Detector Machine

Hot Labels: food,checkweigher machine,automtaic,check weighing machine,glass,bottle,pickle,processing line,price,factory,manufacturer