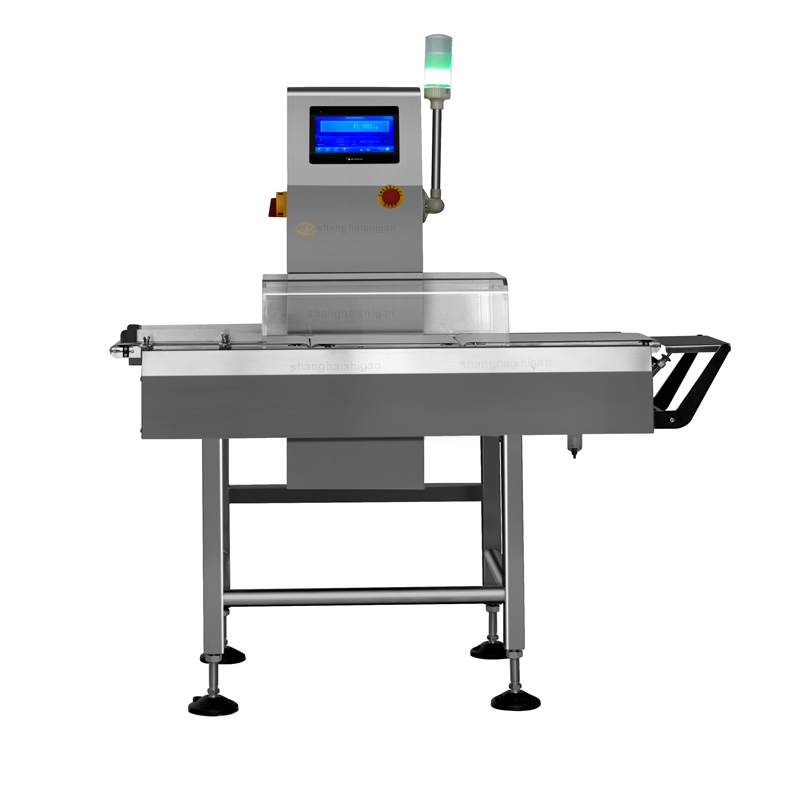

An automatic checkweigher machine is a vital component in the manufacturing and packaging industry, playing a crucial role in ensuring product quality and compliance with regulations. This sophisticated piece of equipment is designed to accurately measure the weight of items as they move along a production line, helping to identify any discrepancies and maintain consistency in the packaging process.

At its core, a high speed checkweigher machine serves as a quality control tool, verifying that products meet specified weight requirements and ensuring that under or overfilled packages are promptly identified and addressed. This is particularly important in industries such as food and pharmaceuticals, where precise measurements are essential for consumer safety and regulatory compliance.

The operation of a online automatic checkw eigher machine involves the use of advanced technology, including load cells and sensors, to accurately measure the weight of individual items or packages. As products pass through the machine, they are swiftly and accurately weighed, with any deviations from the target weight triggering alerts or automated adjustments to maintain consistency.

In addition to weight verification, dynamic checkweighers can also perform other functions such as rejecting non-compliant items, recording weight data for quality control purposes, and integrating with other production line equipment for seamless operation. This level of automation and integration helps streamline the packaging process and minimize the risk of errors or inconsistencies.

The benefits of incorporating a automatic check weighing machine into a production line are numerous. By ensuring that products are consistently package within specified weight tolerances, manufacturers can enhance customer satisfaction, minimize product giveaway, and reduce the risk of costly recalls due to non-compliant packaging. Furthermore, the data collected by automatic checkweigher machines can provide valuable insights into production efficiency and help identify areas for improvement.

In the food industry, online checkweigher machines play a critical role in ensuring compliance with regulations related to product labeling and consumer protection. By accurately verifying the weight of packaged food items, manufacturers can adhere to legal requirements and maintain consumer trust. Similarly, in the pharmaceutical industry, high speed and accuracy checkweigher machines help uphold stringent quality standards and ensure that medication dosages are precise and consistent.

As technology continues to advance, production line checkweigher machines are evolving to offer enhanced capabilities and integration with other production line equipment. Modern checkweigher systems may incorporate features such as advanced data analytics, remote monitoring, and connectivity with enterprise resource planning (ERP) systems to provide real-time insights into production performance and facilitate proactive maintenance.

Overall, the online checkweigher machine plays a pivotal role in modern manufacturing and packaging operations, contributing to product quality, regulatory compliance, and operational efficiency. Its ability to accurately measure and verify the weight of items ensures that consumers receive consistently packaged products while enabling manufacturers to uphold quality standards and optimize production processes. With ongoing advancements in technology, the conveyor belt checkweigher machine continues to be a valuable asset for industries where precision and consistency are paramount.

Related Products

Food Package Automatic Sorting Multi-level Checkweigher

Capsule Tablet Checkweigher for Pharmaceutical

Professional Industrial Metal Detection Equipment

Industrial Metal Detectors for Plastics Conveyor