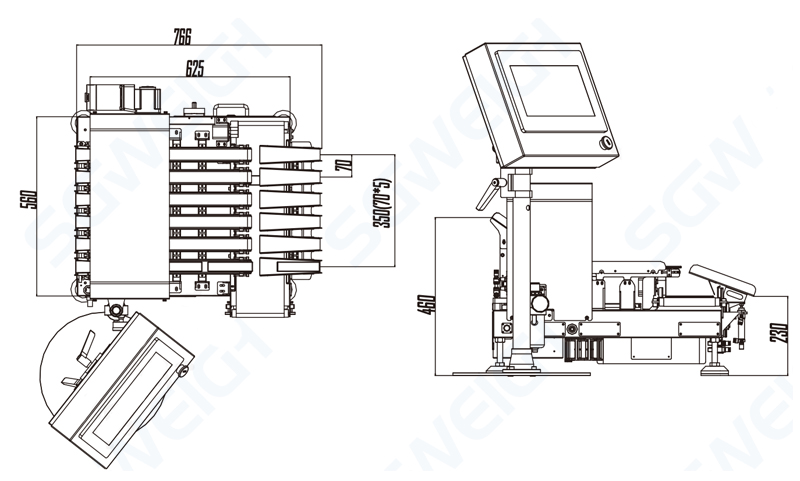

Multi-row High-precision Checkweigher Strip Package Checkweighing System

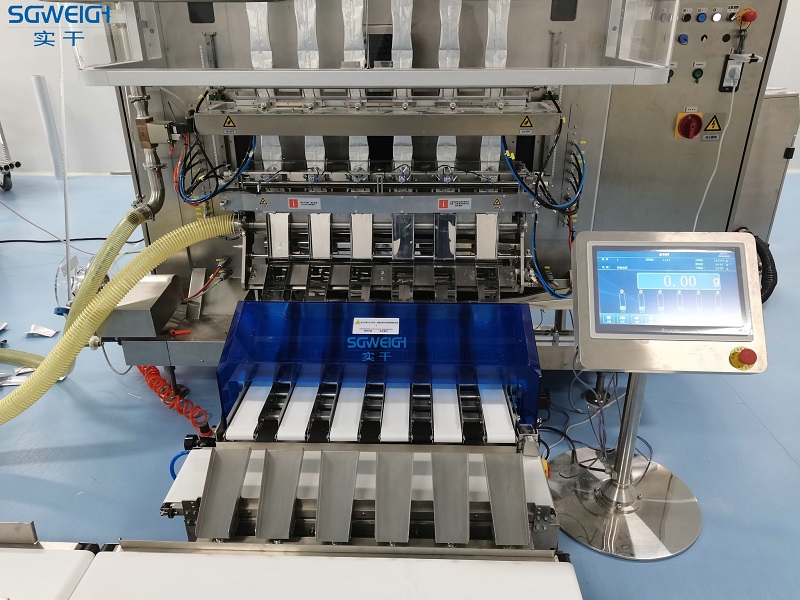

This multi-lane strip package checkweighing system detects the weight of products on the production line by high-speed dynamic weight reading, and can accurately detect products with unqualified weight in the continuous production line, and comprehensively display the quantity, speed, weight, product information and other information on the human-machine interface. The multi-row high-precision checkweigher is used for packaging inspection, so as to achieve full inspection of products before leaving the factory, and also achieve the effect of saving labor.

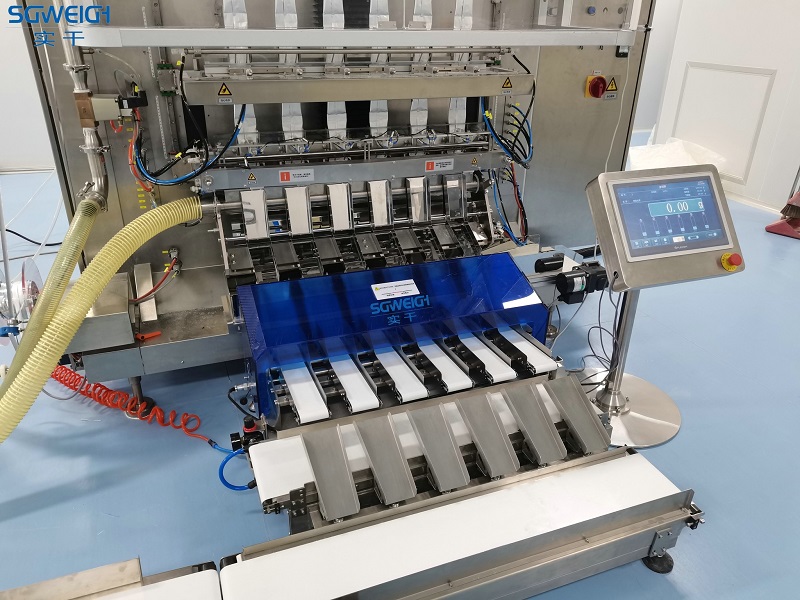

Multi-lane strip package checkweighing system photos

Multi-row High-precision Checkweigher Strip Package Checkweighing System

1. Greatly improve the detection speed per unit time

2. Effectively prevent defective products such as empty bags, underweight, overweight, etc.

3. Count the products that pass through and automatically remove unqualified products through the sorting device

4. Can be used with multi-column packaging machines, automatic filling machines, metal detectors, etc.

5. Can be customized according to the requirements of the on-site production line, and can be configured with automatic barcode scanning and inkjet systems

6. The number of detection columns can be customized according to customer needs (such as double columns, four columns, six columns, ten columns, etc.)

7. Each channel can eliminate unqualified products separately.

8. The number of consecutive unqualified products in each channel can be modify.

9. Statistical data of each channel: real-time result display, trend chart display, histogram display.

Model SG-Multi-row machine

Weighing range 1-30g

Minimum scale 0.01g

Sorting speed Maximum 50 pieces/minute (one channel)

Conveying speed 20-100m/min

Operation mode Touch operation

Conveying direction Can be placed according to the actual situation on site

Rejection method Lifting rejection

Belt height from the ground 450±50mm (can be customized according to customer requirements)

Machine structure Stainless steel (SUS304)

Power supply 220V 50-60HZ

Power about 1000W

Wind shield Thick acrylic (to avoid airflow interference)

Multi-row high-precision checkweigher is widely use in food, pharmaceuticals, beverages, health products, daily chemicals, agricultural and sideline products, hardware, toys, electronics, digital, printing and other industries for multi-row weighing of strip packaging products.

Our company has rich experience in multi-row checkweigher manufacturing. We can provide you with the most cost-effective online checkweigher solution according to your actual needs. If you need, please feel free to contact us.

Shanghai Shigan Industrial Co., Ltd. was founded in 2010 and is located in Shanghai. Shanghai Shigan has an independent R&D organization, a complete production and manufacturing system and a huge marketing service network. It is an international assembly line testing equipment manufacturer integrating R&D, manufacturing, marketing and service. At present, our company’s products have pass the CE EU certification and are export to many countries and regions such as Europe, the United States, Singapore, Thailand, etc. The main products are: Checkweigher Machine、Automatic Check Weigher、Capsule Tablet Checkweigher、Checkweigher with Labeling Machine Combo、High Accuracy Checkweigher、High Speed Checkweigher、Inline Weight Checker、Multi-lane Checkweigher、Weight Sorting Machine、Digital Metal detector、Capsule Tablet Metal Detector、Checkweigher and Metal Detector Combo、Food Metal Detector、Industrial Metal Detector、Pharmaceutical Metal Detector

Packaging:

1. Outer packaging: standard export wooden box

2. Inner packaging: carefully stretched film is use to wrap the product, hardwood board + strong bandage to fix the corners.

3. Inspection team: Professional personnel will inspect and sort your goods.

Multi-row High-precision Checkweigher Strip Package Checkweighing System

1. Pre-sales consultation

We will help you customize the appropriate weighing and packaging solutions according to your requirements and specific circumstances.

2. Installation service

We will dispatch professional technicians to carry out on-site installation and commissioning as needed.

3. Maintenance service

Shigan provides long-term maintenance services, providing any repair parts free of charge during the warranty period, and only charges after the warranty period expires.

4. Staff training

Shigan provides free technical training for our customers to fully master the correct product maintenance technology.

5. Customer service

Shigan designs customized production lines for customers based on specific weighing and packaging factors such as product output, packaging method and factory area.

Related Products

Automatic Multi Column Checkweigher for Strickpack Granular

SG-1X Tube Automtaic Checkweigher Machine

Food Pharmaceutical Check Weigher Doypack

Sauce Jam Stick pack Multi Lane Packing Machine

Vertical Throat Metal Detector for Powder & Granule

1kg Coffee Beans Large Bag Checkweigher with Medium Speed

Precision Sample Checkweigher for Capsule and Tablet

Bottled Liquid Rotary Weight Checker Intelligent

Hot Labels: Multi-row high-precision checkweigher strip Package Checkweighing System