Ultra-high Speed Checkweigher for Bottle Solution Clamping Conveyor Check Weigher Machine Price

Product Introduction

This ultra-high speed checkweigher for bottle detects the weight of bottled products on the production line by high-speed dynamic weight reading. It can accurately detect products with unqualified weight in the continuous production line, and perform upper and lower line discrimination or automatic weight sorting control accordingly. It is particularly suitable for missing parts inspection in packaged products. This bottle clamping conveyor check weigher machine has a compact design, fast speed, high precision, stable operation, and easy operation. It can provide various rejection systems and integrate with upstream and downstream equipment into a complete packaging line. Any OEM and customer design orders are welcome! If you are interested in our products, please feel free to contact us.

Ultra-high speed checkweigher for bottle pictures

Technical Parameter

Type SG-150HH

Weighing Range 3-500g

Limited of product L: 100 W:150 H: 2-150mm

Accuracy ±0.1g Depends on product

Division Scale 0.1g

Belt Speed 0- 110 m/min

Max Speed 450 pcs/min

Belt Width 150mm

Machine Weight 140kg

Power Supply 50HZ

Power 200W

Main Material SU304 stainless steel

The above parameters are for reference only. Our professional engineers will rigorously evaluate the production line characteristics, specifications and environmental factors to design the most suitable checkweigher solution for your production line to meet the different needs of various complex production lines.

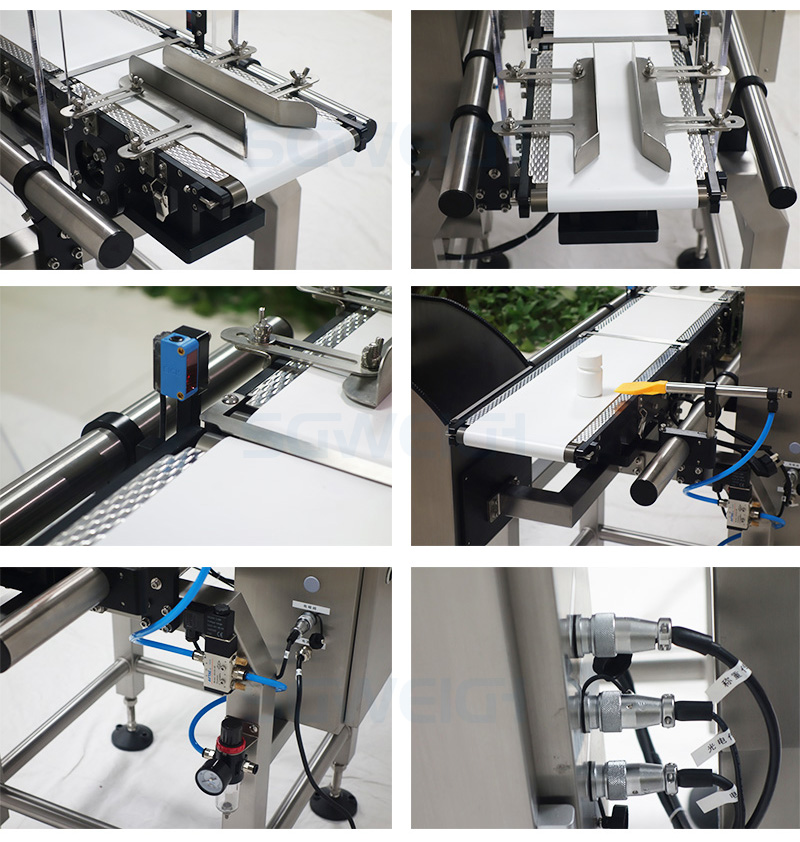

Product Details

- Strong practicality: 10-inch high-color, high-resolution human-machine interface, easy and friendly operation;

- High stability: 24-hour high-speed, high-precision operation. Advanced and rigorous design concept greatly reduces mechanical system failures and improves production efficiency;

- High speed, high precision: Adopts high-speed and high-precision German HBM sensor

- Material accessories: The entire body structure is made of 304 stainless steel, which is anti-theft, anti-corrosion and has a long service life.

- Weight inspection data is equipped with a USB interface as standard, and can be exported to EXCEL tables

- Easy maintenance: Unique conveyor belt structure design, modular design, easy disassembly and cleaning, protection level IP65.

- Easy docking: Adopts DC brushless motor, which is more stable and has a smaller and more delicate structure. Suitable for greater speed requirements.

- Easy switching: 99 product formulas can be stored, and product parameters can be changed with one click.

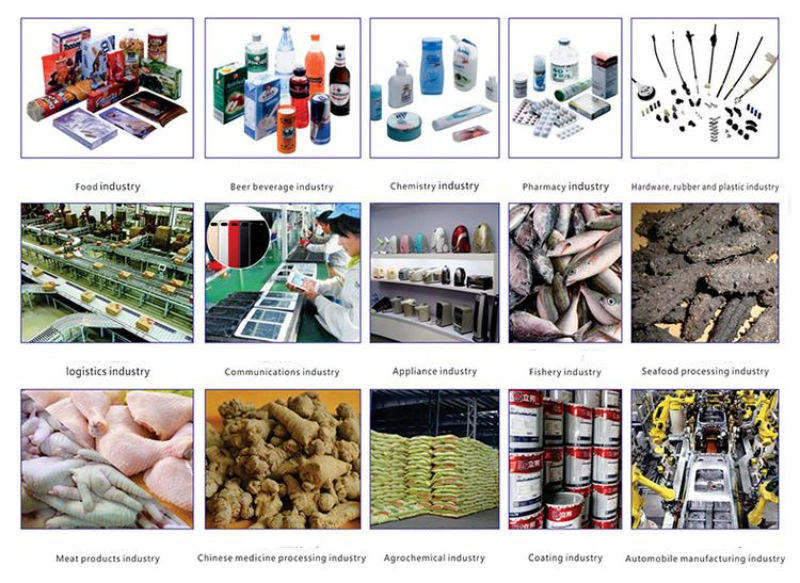

Application Scope

Ultra-high speed checkweigher for bottle is widely used in many industries such as electronic hardware, pharmaceuticals, food, chemicals, beverages, health products, etc. For example, it can be used in the food industry to check the weight of bread, cakes, ham, instant noodles, frozen foods, food additives, preservatives, etc., as well as the weight of packaged products such as bags, pouches, boxes, jars, cans, cartons, etc.

Company Profile

1.OEM Experiences above 14 Years In checkweigher machine, metal detector Industry

2.Factory Manufacturing Enterprise Provide with you Competitive Price and superior quality

3. Have stable supply chain which can guarantee our product quality and prompt delivery

4. Strict QC process to guarantee quality.

5.Trial Order small quantity for retail and wholesale are accepted

6. Fully equipped with advanced machines and Experience workers

7.Sincere Service!(Effective pre-sale communication+Good after sale service )

8.Various equipment to supply your need

Our Customers

Our Exhibition

Packing & Shipping

The Delivery Date: After receiving the payment, the delivery date will be within 15-30 working days

Packaging: Protective film + wooden case

Logistics: Air, sea or express (DHL, etc.)

The Freight: The cost of transport depends on the destination, mode of transport and the weight of the goods

Pay: T/T, Western Union, paypal

After-sale Service

Consultation and Assessment: Understand your requirements, production processes and quality control goals to determine the best checkweigher solution for your specific needs.

Product Demonstration: Get a visual understanding of the equipment in action and directly assess its performance.

Installation and Commissioning: After purchase, the checkweigher is install and commissioned by trained technicians to ensure it operates correctly and integrates seamlessly into your production line.

Technical Support: Ongoing technical support is provided to resolve any questions, issues or maintenance needs that arise during the operation of the checkweigher.

Warranty Coverage: 1-year warranty, lifetime repairs.

We aim to provide our customers with the right solutions, support and peace of mind throughout the lifecycle of the equipment, ensuring that the checkweigher meets your needs and provides long-term value.

Related Products

20kg Large Range Roller Checkweigher for Industrial

Online Food Beverage Checkweigher Quantitative

Box Packaging Hardware Assembly Line Checkweigher

Dynamic Meat Sauce Pipeline Metal Detector for Food

High Precision Capsule Checkweigher Manufacturer

Super-Efficient Bottle Check Weigher Conveyor

Hot Labels: ultra-high speed checkweigher,bottle,solution,clamping conveyor,check weigher machine,price,factory,manufacturer,supplier